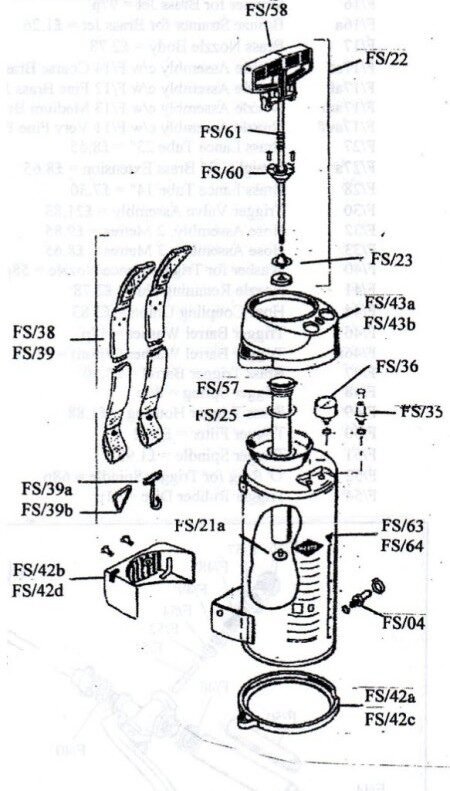

Sprayers Body and Parts

1G/5Ltr Sprayer Complete

2G/10Ltr Sprayer Complete

1G/5Ltr Stainless Steel Sprayer Complete

2G/10Ltr Stainless Stool Sprayer Complete

2GST Single Trolley for Sprayer

2GDT Double Trolley for Sprayers

FS/04 House Outlet Union

FS/2la Black Footvalve Plug

FS/22 Piston Rod and Handle

FS/23 Washer and Piston End Set

FS/25 Pump Sealing Washer

F/32 PVC Hose Assembly, 3 metres

F/33 PVC Hose Assembly. 2 metres

F/34 Seal Kit (Nitrile)

F/34a Seal Kit (Vition)

FS/35 Safety Valve

FS/36 Pressure Gauge

FS/38 Carrying Strap for 5Ltr

FS/39 Carrying Strap for 10Ltr

FS/39a Triangle for Straps

FS/39b Hook for Straps

FS/42a lG (5Ltr) Base Ring

FS/42b 1G (5Ltr) Rear Base Tank Cover

FS/42c 2G (10Ltr) Base Ring

FS42d 2G (l0Ltr) Rear Base Tank Cover

FS/43a 1G (5Ltr) Filler Funnel

FS/43b 2G (l0Ltr) Filler Funnel

FS/45 Air Adaptor (instead of manual pump assembly)

FS/57 Pump Barrel Only

FS/58 Pump Unit Complete

FS/60 Pump Cap

FS/61 Buffer Spring

FS/63 1G (5Ltr) Body Bare

FS/64 2G (10Ltr) Body Bare

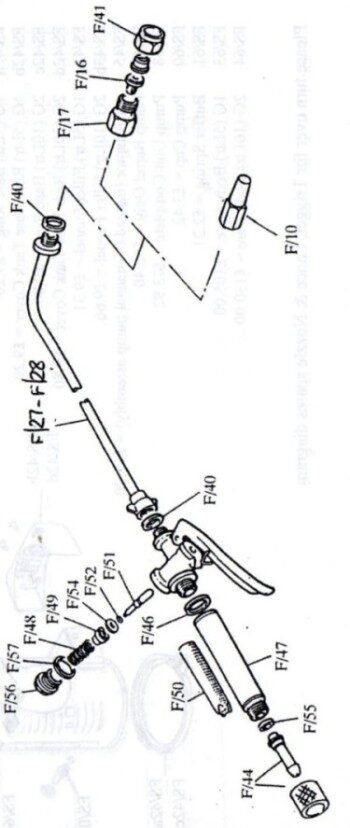

Triggers Lances and Nozzles Fittings

The range of Triggers. Lances and Nozzles fit both old and new type Sprayers.

The hoses have different attachments to the base of the sprayer.

F/04 on the old yellow and blue sprayer and FS/04 on the yellow and black sprayers.

F/10 Adustable Nozzle Assembly

F/11 Very Brass Fine Jet

F/12 Fine Brass Jet

F/13 Medium Brass Jet

F/14 Coarse Brass Jet

F/16 Strainer for Brass Jet

F/16a Bronze Strainer for Brass Jet

F/17 Brass Nozzle Body

F/17ac Nozzle Assembly c/w F/14 Coarse Brass Jet

F/I7af Nozzle Assembly c/w F/12 Fine Brass Jet

F/I7am Nozzle Assembly c/w F/13 Medium Brass Jet

F/17avf Nozzle Assembly c/w F/l 1 Very Fine Brass Jet

F/27 Brass Lance Tube 23″

F/27a Straight 23″ Brass Extension

F/28 Brass Lance Tube 14″

F/30 Trigger Valve Assembly

F/32 Hose Assembly. 2 Metres

F/33 Hose Assembly. 3 Metres

F/40 Washer for Trigger/Lance/Nozzle

F/41 Nozzle Retaining Nut

F/44 Hose Coupling Union

F/46 Trigger Barrel Washer

F/46a Trigger Barrel Washer (Viton)

F/47 Brass Trigger Barrel

F/48 Trigger Spring

F/49 Brass Trigger Housing

F/50 Trigger Filter

F/51 Trigger Spindle

F/52 ‘O’ Ring for Trigger Spindle

F/S4 Trigger Rubber Disc

Mexican Sprayer

The hoses have different attachments to the base of the sprayer.

F/04 on the old yellow and blue sprayer (before June 2010) and FS/04 on the yellow and black sprayer afterwards

lG/5Ltr Maxican Complete

2G/10Ltr Maxican Complete

FS/04 Hose Outlet Union

FS/21a Black Footvalve Plug

FS/22 Piston Rod and Handle

FS/23 Washer and Piston End Set

FS/25 Pump Sealing Washer

F/32 Hose Assembly, 2 Metres

F/33 Ho* Assembly, 3 Metres

F/34 Seal Kit

F/35 Safety Valve

FS/36 Pressure Gauge

FS/38 Carrying Strap for 5Ltr

FS/39 Carrying Strap for 10Ltr

FS/39a Triangle for Straps

FS/G9b Hook for Straps

FS/42a 1G (5Ltr) Base Ring

FS/42b 1G (5Ltr) Rear Base Tank Cover

FS/42c 2G (10Ltr) Base Ring

FS/42d 2G (10Ltr) Rear Base Tank Cover

FS/43a 1G (5Ltr) Filler Funnel

FS/43b 2G (10Ltr) Filler Funnel

FS/58 Pump Barrel Only

FS/59 Pump Unit Complete

FS/60 Pump Cap

FS/61 Buffer Spring

FS/63 1G (5Ltr) Body Bare

FS/64 2G (10Ltr)Body Bare

FS/45 Air Adaptor (instead of manual pump assembly)

Maxican Lances

The hoses have different attachments to the base of the F/04 on the old yellow and blue sprayer and FS/04 on the yellow and black sprayers.

F/18 Nylon Footvalve for Pump

F/20 Footvalve Spring1

F/30 Trigger Valve Assembly1

F/32 Hose Assembly, 2 Metres1

F/33 Hose Assembly, 3 Metres1

F/40 Washer for Trigger/Lance/Nozzle1

F/41 Nozzle Retaining Nut1

F/44 Hose Coupling Union1

F/46 Trigger Barrel Washer1

F/46a Trigger Barrel Washer (Viton)1

F/47 Brass Trigger Barrel1

F/48 Trigger Spring1

F/49 Brass Trigger Housing1

F/50 Trigger Filter

F/51 Trigger Spindle

F/52 ‘O’ Ring for Trigger Spindle

F/54 Trigger Rubber Disc

F/55 Hose Leather Washer

F/56 Trigger Base Cap

F/57 Trigger Base Cap Washer

F/65m Filler Spout

F/66m Brass 1 /4″bsp Socket

F/67m Brass Tip for Maxican Spout

Operating Instructions

The Port A park ‘CS’ Sprayer Operating Instructions

1 Gallon Sprayer – 5 Litres

2 Gallon Sprayer – 10 Litres

ASSEMBLY: The units are supplied complete with trigger valve assembly, lance and nozzle assembly These should be screwed together tightly making sure that each scaling washer is in place. Before fitting the nozzle and jet. make sure they arc clear by blowing through them before assembling Each unit is fitted with a safety valve, factory adjusted to a pressure of 80p.s.i. On no account must this be tampered with. Four sizes of jets arc available, if the type of spray cannot be obtained by varying the pressure you might need a fine or coarser jet. There is also an adjustable nozzle available.

OPERATION: Remove the pump by pressing down the handle, engaging the lugs and unscrewing the whole pump assembly Pour in your fluid, then replace the pump by screwing it back in. hand tight Pump the unit upto 60p.s.i., direct the nozzle in the direction you wish to spray and press the trigger handle If the spray is too fine or forceful, reduce the operating pressure by pressing the red button on the top of the sprayer When the operating pressure has been reduced by 10p.s.i. try the spray again, and when the ideal pressure has been reached for your application, maintain the pressure at or near this figure With some viscous fluids it can be an advantage by removing the F/50 Trigger Filter from the trigger valve

MAINTENANCE: It is vitally important that the unit is always kept in a clean condition, and it should be washed out regularly with a suitable solvent It should never by left with any residue of fluid when not in use, particularly when using any material which may thicken up or settle out when standing

PUMP MAINTENANCE: The F/24 Piston “O” Ring should be kept well greased if the unit is being used with fluid which have no lubricating properties. The “O” Ring can be examined by unscrewing the F/60 Pump Cap from the cylinder and withdrawing the F/22 Piston Rod and Handle. If the piston rises after pumping, the cause is a dirty or worn footvalve in the base of the pump assembly. This can be cleaned or replaced by unscrewing the F/21A Footvalve Plug, taking out the F/20 Spring and then the footvalve which can then be examined

LOSS OF PRESSURE: This can be caused by damage to the F/25 Pump Seal, or otherwise by dirt under the sealing of the F/37 Relief Valve If the latter appears to be the cause, carefully remove the circlip in the top of the valve body and clean or replace the valve washer and spring

If you experience other problems or require further information or assistance, please do not hesitate to contact our sales office on the above number*, who will be happy to help.